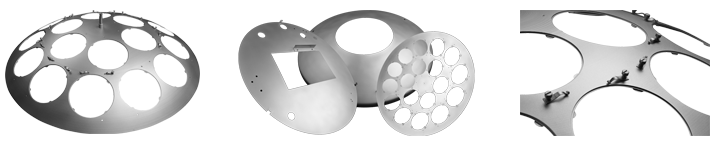

As a direct result of growing customer demand for shield kit cleaning services, VEM has a dedicated facility in Dallas, Texas which provides precision parts cleaning and surface treatment of PVD shield kits, as well as other process kit types, for manufacturers in the semiconductor, photonics, LED, data storage, aerospace & defense and life sciences industries. In addition to NEW, automated robotic controlled Twin Wire Arc Spray (TWAS) and Plasma Spray capability, the investment includes equipment for ultrasonic cleaning, clean room drying, bake out, new cleaning processes, and a clean room certified to Class 100.

The Twin Wire Arc Spray is a leading-edge technology that increases mean wafer between clean (MWBC) by applying enhanced, textured coating on critical chamber components. The textured coating provides increased surface area of the parts and allows more material to be deposited as well as better deposition adhesion for better particle control. The Plasma Spray system allows for the ability to coat chamber components with high purity ceramic films, such as Al2O3 and Y2O3 to extend part life and improve surface cleanliness of parts.

- Inventory Kit Control

- Traceability

- Customer parts tracked in VEM ERP system

- Bar Code Tracking

- Deposition Removal

- Mechanical and bead blast

- Chemical clean

- Texturing to Specifications

- AI203 and SiC media

- Surface roughness measurements

- TWAS and Plasma Spray

- Twin Wire Arc Spray (TWAS)

- AI2O3 & Y2O3

- Pressure Washing

- Ultrasonication in Class 100 Clean Room

- Drying, Inspection and Packaging

- Nitrogen drying stations

- Heat lamps

- Class 100 clean room environment

- Critical Part Measurements

- Qiii Surface Particle Detector

- Ultra Violet light

- Metal Reclamation

- Provide excellent rate of return and settlement times

- Pure metals, chamber scrapings, mixed metals and bead blasting materials