VEM continues to innovate by having one of the largest, cutting-edge Vacuum Hot Presses in the industry, allowing customers to develop some of the most advanced powder metallurgy targets available in the market. VEM's VHP is capable of:

- 250 tons of pressure, reaching temperatures of 2,000° C, for targets ranging from 50mm - 450mm

- Achieving a Vacuum Atmosphere of 10-3 Torr

- Inert Gas Atmosphere

- Process Logic Controlled (PLC), ensuring repeatability and tracking of Statistical Product Control (SPC) data.

Some of the target materials available for hot press are Al2O3, AZO, BST, CrB2+SiC+other materials, CrSi-SiC, ITO, LiCo2O3, MoSi, NbTa, NiCrSi, NiFe+other materials, Ru, SiAl, SiCr, Ta, TaSi, TiAl, WTi, and WSi.

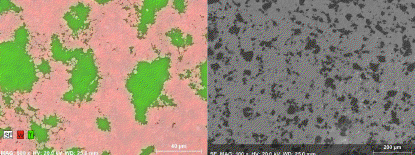

Product development for Powder Metallurgy Targets

- Metallography

- Physical Characterization

- Able to achieve desired density based on pressure and sintering time.

- Chemical Characterization

- We can blend materials within 1 AT% of the desired composition

- We can develop methods to reduce or increase specific key elements (i.e. O, C, Na, K, Li etc.)